Search

It’s All About Adhesion

Also Purchased

Pull-Off Adhesion Testing of Coatings - Improve Your Technique

Product Number:

41215-893-SG

Publication Date:

2015

$20.00

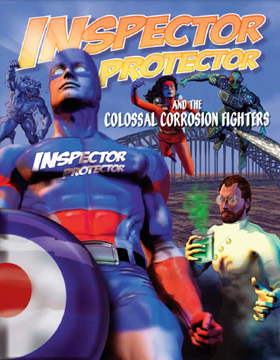

Inspector Protector and the Colossal Corrosion Fighters

Product Number:

37585

ISBN:

Inspector Protector

$2.00

Recently viewed