Search

Reports

View as

Sort by

Display

per page

NACE Publication 1F192-2013, "Use of Corrosion-Resistant Alloys in Oilfield Environments"

Product Number:

24010-SG

Publication Date:

2013

$179.00

NACE Publication 21410-SG Selection of Pipeline Flow and Internal Corrosion Models

Product Number:

21410-SG

ISBN:

1-57590-353-9

Publication Date:

2016

$109.00

NACE PUBLICATION 21414-SG (2016 Edition), “Maintenance Overcoating of Railcar Exteriors”

Product Number:

21414-SG

ISBN:

1-57590-363-6

Publication Date:

2016

$109.00

NACE Publication 21428-2018 - Corrosion Inhibiting Admixtures for Reinforced Concrete-A State of the Art Report

Product Number:

21428-SG

Publication Date:

2018

$109.00

NACE Publication 21429-2018-SG - State of the Art Report on Corrosion-Resistant Reinforcement

Product Number:

21429-SG

Publication Date:

2018

$109.00

NACE Publication 30105-2005-SG, Electrical Isolation/Continuity and Coating Issues for Offshore Pipeline Cathodic Protection Systems

Product Number:

24228-SG

ISBN:

NACE Pub 30105

$109.00

NACE Publication 31105-2005-SG, Dynamic Scale Inhibitor Evaluation Apparatus and Procedures in Oil and Gas Production

Product Number:

24225-SG

ISBN:

NACE Pub 31105

Publication Date:

2005

$109.00

NACE Publication 31205-2006-SG, Selection, Application, and Evaluation of Biocides in the Oil and Gas Industry

Product Number:

24227-SG

ISBN:

NACE Pub 31205

$109.00

NACE Publication 31215-2014, “Laboratory Evaluation of Corrosion Inhibitors Used in the Oil and Gas Industry

Product Number:

24259-SG

Publication Date:

2014

$179.00

NACE Publication 34101-2001-SG, Refinery Injection and Process Mixing Points

Product Number:

24215-SG

Publication Date:

2001

$109.00

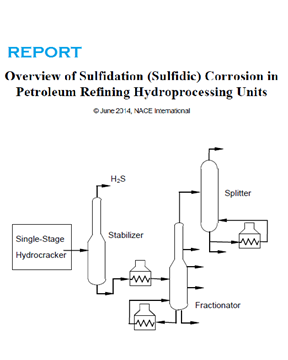

NACE Publication 34103-2014-SG, Overview of Sulfidation (Sulfidic) Corrosion in Petroleum Refining Hydroprocessing Units

Product Number:

24222-SG

Publication Date:

2014

$109.00